Quantity:

Total:

View Basket

Tel: +44 (0)151 643 9555

Last Modified 01/11/23

Email: sales@prestigeautotrim.com

© Prestige Autotrim Products Ltd 1980-2026

Precision Made For A Precise Fit

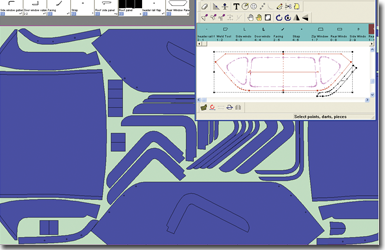

Precision pattern making and continuous investment in the latest CAD/CAM equipment means that Prestige Car Hoods & Interior Trim are made to more exacting standards than many others.

Every product is patterned and developed in our dedicated Design Studio by our expert pattern makers with over 35 years experience in developing car hoods and interior trim for the British Motor Industry.

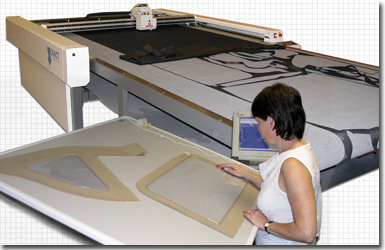

We utilise the latest computer controlled cutting machines to ensure items are cut to an accuracy of +-0.01mm and offer a precise fit.

Precision pattern making and continuous investment in the latest CAD/CAM equipment means that Prestige Car Hoods & Interior Trim are made to more exacting standards than many others.

Every product is patterned and developed in our dedicated Design Studio by our expert pattern makers with over 35 years experience in developing car hoods and interior trim for the British Motor Industry.

We utilise the latest computer controlled cutting machines to ensure items are cut to an accuracy of +-0.01mm and offer a precise fit.

Digital Patterns Guarantee Accuracy

Digitised pattern making and computer controlled cutting machines accurate to +-0.01mm ensure the highest standards of quality and fit.

This Hi Tech manufacturing process means that our products are now even better than many of the original equipment hoods and trim of the past. We continually strive to ensure our products are widely considered equal to or better than those installed originally when the vehicle was new.

Digitised pattern making and computer controlled cutting machines accurate to +-0.01mm ensure the highest standards of quality and fit.

This Hi Tech manufacturing process means that our products are now even better than many of the original equipment hoods and trim of the past. We continually strive to ensure our products are widely considered equal to or better than those installed originally when the vehicle was new.

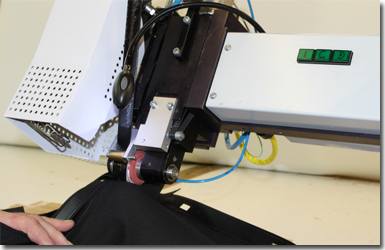

Modern Sewing Technology

All car hoods and interior trim require the specialised skills of a fully trained sewing machinist. Our machine operators have been in this business most of their working lives and provide unsurpassed skill and knowledge in car hood and trim manufacturing.

To aid them in producing the finest car hoods and interior trim, we continue to invest in the latest automated machines and the machine operators work closely with the Design Studio to develop and evaluate new manufacturing techniques.

All car hoods and interior trim require the specialised skills of a fully trained sewing machinist. Our machine operators have been in this business most of their working lives and provide unsurpassed skill and knowledge in car hood and trim manufacturing.

To aid them in producing the finest car hoods and interior trim, we continue to invest in the latest automated machines and the machine operators work closely with the Design Studio to develop and evaluate new manufacturing techniques.

High Frequency Welding

High Frequency Welding Presses are used to bond Wopavin 9101 window plastic into car hoods. High frequency welding is also used on main roof seams. This is a factory original process that gives the hood a factory original appearance, adds considerable strength to the seams and prevents any water ingress through the seams.

High Frequency Welding Presses are used to bond Wopavin 9101 window plastic into car hoods. High frequency welding is also used on main roof seams. This is a factory original process that gives the hood a factory original appearance, adds considerable strength to the seams and prevents any water ingress through the seams.

Hot Air Seam Sealing

Specialised hot air seam sealing technology is a modern process that allows car hood roof seams to be sealed from the inside quickly and precisely.

It is a factory original process for most modern convertibles, such as Porsche and BMW.

Specialised hot air seam sealing technology is a modern process that allows car hood roof seams to be sealed from the inside quickly and precisely.

It is a factory original process for most modern convertibles, such as Porsche and BMW.